Product Description

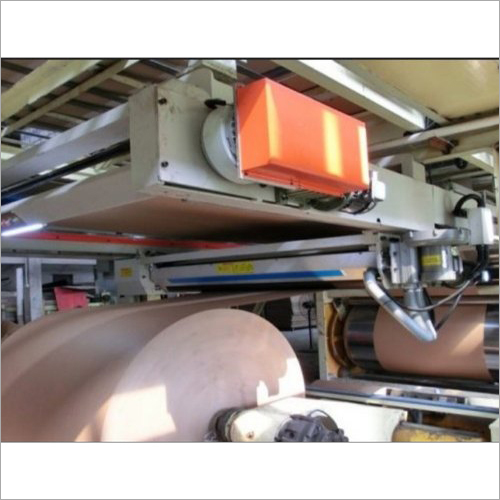

An automatic splicer for a corrugated machine is a piece of equipment used in the corrugated cardboard manufacturing industry. Corrugated cardboard is commonly used in packaging materials, and corrugated machines are used to produce it. The automatic splicer plays a crucial role in ensuring uninterrupted production.

Here's how it works:

1. Material Splicing: The automatic splicer is designed to splice or join two rolls of corrugated material seamlessly. When one roll of corrugated material is about to run out, the splicer automatically switches to a new roll.

2. Seamless Transition: The splicer's main function is to make sure there is a continuous feed of corrugated material into the corrugated machine. This is achieved by precisely aligning the end of the expiring roll with the start of the new roll, ensuring a seamless transition without stopping the machine.

3. Sensors and Control: The automatic splicer uses sensors to detect when the material on the expiring roll is about to run out. When this is detected, the splicer's control system activates, and it starts the splicing process.

4. Cutting and Gluing: The splicer will cut the end of the expiring roll at an angle and apply glue to create a splice. This is done while the corrugated machine continues running. The angle of the cut helps ensure a smooth transition as the corrugated material is fed into the machine.

5. Quality Control: The splicer system often includes quality control mechanisms to monitor the splice's integrity and quality, making sure it's strong and won't cause issues during the production process.

6. Operator Interface: There is usually an operator interface where the machine's settings and operations can be monitored and adjusted as needed.

# Applications of Automatic Splicer Automatic Corrugated Machine:

1. Continuous Production: The most critical application is to maintain continuous production. Automatic splicers eliminate the need for manual roll changes, reducing downtime, and ensuring the corrugated machine runs without interruptions.

2. Increased Efficiency: Automatic splicers improve the efficiency of the corrugated cardboard manufacturing process by optimizing the use of raw materials. They minimize material waste by using the entire length of each roll.

3. Labor Savings: By automating the splicing process, manual labor is not required for roll changes, allowing operators to focus on other tasks and reducing the need for skilled personnel for this repetitive job.

4. Product Consistency: Splicers ensure consistent quality by providing precise and reliable splices. This consistency is vital for corrugated cardboard products used in packaging to meet quality and performance standards.

5. High-Speed Production: Automatic splicers are particularly beneficial in high-speed corrugated machine operations where the production rate is rapid. They can keep up with the machine's speed without slowing it down.

6. Reduced Material Waste: Minimizing material waste is environmentally and economically beneficial. Automatic splicers help reduce waste by using the material on the expiring roll to its maximum potential.

7. Quality Control: Some splicer systems include quality control features to inspect the splice and ensure its integrity. This is crucial for preventing defects in the final corrugated products.

8. Flexibility: Automatic splicers are adaptable to different roll sizes and types of corrugated material. This flexibility allows manufacturers to switch between materials easily.

9. Cost Savings: While there is an initial investment in automatic splicing equipment, the long-term cost savings in terms of reduced material waste, increased efficiency, and reduced labor costs can be significant.

10. Safety: Automatic splicers contribute to a safer working environment by reducing the need for manual roll handling, which can be physically demanding and pose injury risks.

# Frequently Asked Questions:

1. What is an automatic splicer in a corrugated machine?

Ans: An automatic splicer is a machine component used in corrugated cardboard manufacturing. Its primary function is to seamlessly switch between rolls of corrugated material to maintain uninterrupted production.

2. Why are automatic splicers used in corrugated machines?

Ans: Automatic splicers are used to eliminate downtime associated with manual roll changes. They ensure a continuous feed of corrugated material into the machine, improving efficiency and reducing waste.

3. How does an automatic splicer work?

Ans: Automatic splicers use sensors to detect when the material on one roll is running out. When this occurs, the splicer cuts the end of the expiring roll at an angle, applies glue, and precisely aligns it with the start of a new roll to create a seamless splice.

4. What are the benefits of using automatic splicers in corrugated machines?

Ans: The benefits include continuous production, increased efficiency, reduced labor requirements, consistent product quality, and a reduction in material waste. They are also essential for high-speed operations.

5. Are automatic splicers adaptable to different roll sizes and materials?

Ans: Yes, automatic splicers are designed to be flexible and can be adjusted to work with various roll sizes and types of corrugated material.

6. Do automatic splicers include quality control features?

Ans: Some automatic splicers come with quality control mechanisms to ensure the integrity of the splice and prevent defects in the final corrugated products.

7. How do automatic splicers contribute to safety in the manufacturing process?

Ans: Automatic splicers reduce the need for manual roll handling, which can be physically demanding and pose injury risks. This contributes to a safer working environment.

8. What is the initial investment required for an automatic splicer?

Ans: The cost of an automatic splicer can vary depending on its features and capacity. While there is an initial investment, the long-term cost savings in terms of reduced waste and increased efficiency can be significant.

9. Are there maintenance requirements for automatic splicers?

Ans: Like any industrial equipment, automatic splicers require regular maintenance to ensure they function properly. Maintenance schedules and requirements may vary depending on the specific machine.

10. Can automatic splicers be retrofitted into existing corrugated machines?

Ans: In many cases, yes. Automatic splicers can often be retrofitted into existing corrugated machines to improve their efficiency and production capabilities.